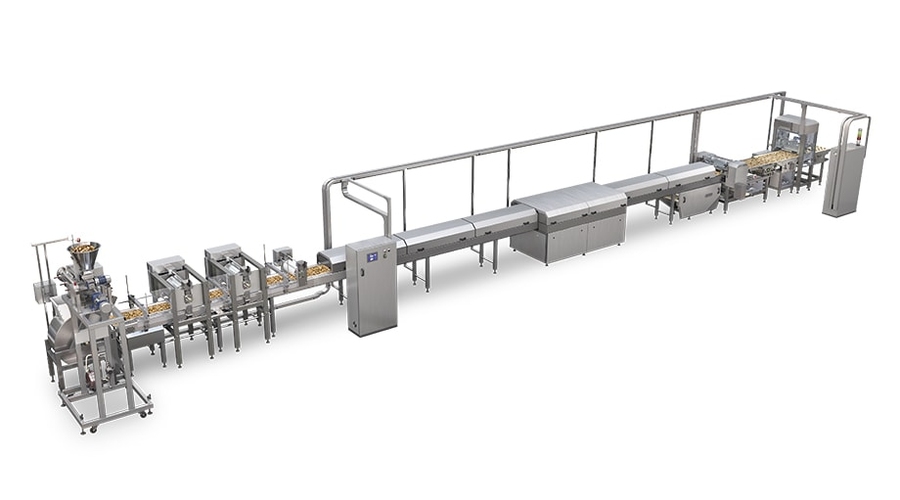

Automatic Line for Cereal Bar Production

The line is designed to form a continuous layer of confectionery mass, cut it precisely into bars of specified sizes, distribute finished products, and feed them to glazing or packaging machines. The complex ensures stable quality and high shape repeatability.

The line is suitable for producing cereal, praline, fruit, protein, whey, caramel, and mixed bars. Thanks to the modular design and available optional modules, the equipment can be easily adapted to specific technological tasks, different recipes, and production scales.

Standard configuration:

- dry ingredients dispenser into the mixer;

- mixer (for blending dry ingredients with syrup);

- layer forming unit with thickness and width control;

- cooling chamber for structure stabilization;

- longitudinal and cross-cutting units for precise bar dimensions (mechanical);

- distribution conveyor for feeding bars to glazing or packaging;

- control system.

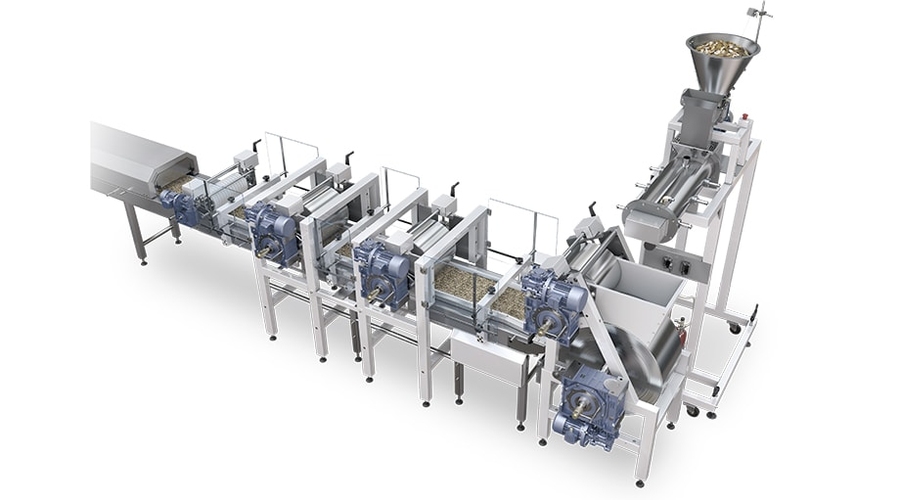

Optional modules:

- dry ingredients mixer into the main mixer;

- belt-bucket conveyor for dry ingredients feeding;

- syrup dosing pump;

- syrup boiler and storage tank;

- nougat layer forming unit;

- caramel layer forming unit;

- ultrasonic knives.

Capacity: up to 500 kg/h

Power: up to 30 kW

All SISPRO TM equipment is manufactured according to the Customer's technical specifications.

We adapt the design, performance, and configuration to the specifics of your production.

The cost is calculated individually – contact us to receive a commercial offer.

Contact us