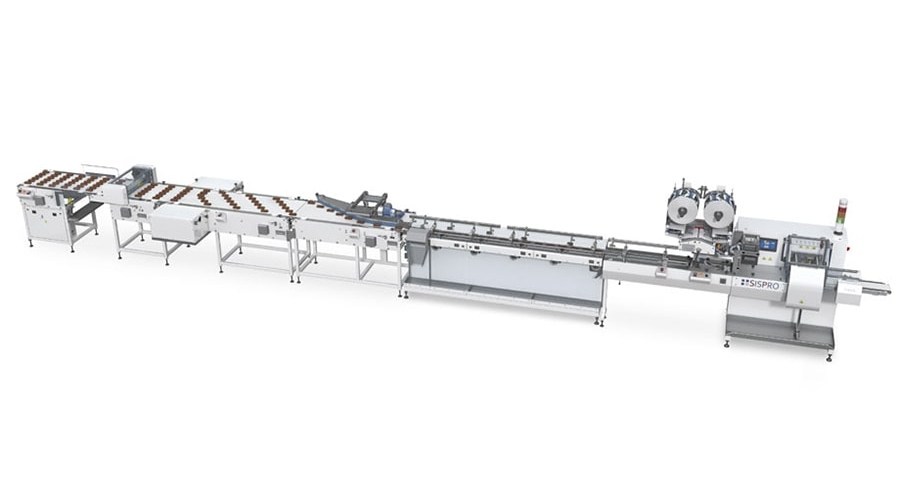

Automated packaging line

The automated packaging line consists of a conveyor system and packaging equipment. It is designed for the transportation, orientation, and feeding of various types of products to a flow-pack machine or other types of packaging equipment.

The conveyor system is engineered considering product characteristics: the belts have a special coating that ensures gentle movement of products sensitive to external impact or prone to sticking. This prevents mechanical damage, weight loss, and product deformation. Adjustable conveyor speed allows precise synchronization with the packaging machine parameters.

The line features a modular design, allowing flexible configuration — adjusting conveyor quantity, length, inclination angle, belt type, and feed speed. All units are synchronized through a centralized control system, ensuring process stability, precision, and high productivity.

All parts in contact with the product are made of food-grade stainless steel, resistant to moisture and cleaning agents. The line complies with HACCP hygiene standards and is suitable for food, pharmaceutical, cosmetic, and technical industries.

Ergonomic design, easy access to components, and quick-clean capability ensure minimal downtime during maintenance or product changeovers.

Technical specifications:

Productivity: up to 1800 kg/h

Power: up to 8 kW

All SISPRO TM equipment is manufactured according to the Customer's technical specifications.

We adapt the design, performance, and configuration to the specifics of your production.

The cost is calculated individually – contact us to receive a commercial offer.

Contact us